One-stop lubrication solution | Discover the way to smoothness | Infomak

PRODUCT PARAMETERS

Description

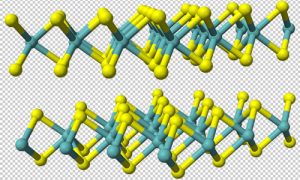

Overview of Graphite Lubricant Graphite Micropowder Graphite Powder

Dry lubricant powders are specialized substances designed to reduce friction and wear between two surfaces without relying on traditional liquid oils or greases. These powders typically consist of fine particles of solid lubricants that form a thin film on the surface when applied, providing a durable and clean lubricating layer. They are particularly useful in high-temperature environments, vacuum conditions, or where oil or grease cannot be used due to contamination concerns.

Features of Graphite Lubricant Graphite Micropowder Graphite Powder

Low Friction: Reduces friction between surfaces, improving efficiency and reducing wear, similar to conventional lubricants.

Heat Resistance: Suitable for high-temperature applications since they do not degrade or evaporate easily like some liquid lubricants.

Clean Operation: Leaves no residue, making it ideal for cleanroom environments, food processing, or where cleanliness is paramount.

Corrosion Resistance: Some dry lubricants provide a protective layer that inhibits corrosion and rust formation on metal surfaces.

Longevity: Offers extended service life compared to wet lubricants due to their adherence and resistance to washout or evaporation.

Versatility: Can be applied to a wide range of materials and surfaces, including metals, plastics, ceramics, and composites.

(Graphite Lubricant Graphite Micropowder Graphite Powder)

Parameters of Graphite Lubricant Graphite Micropowder Graphite Powder

Graphite lubricants can have different types and grades, such as polytetrafluoroethylene (PTFE) lubricants, silicone oils, silicone greases, silicone grease, and more. Each type of graphite lubricant has its own properties, including:

* Chemical stability: Some graphite lubricants may be resistant to certain chemicals or extreme temperatures, while others may not.

* Water resistance: Some graphite lubricants may be water-resistant, making them suitable for use in wet environments.

* Friction: The effectiveness of the graphite lubricant in reducing friction between moving parts depends on factors such as particle size, distribution, and compatibility with other materials.

The parameter “graphite powder” refers to the size and shape of the particles used in the graphite lubricant. Graphite powders can come in various sizes and shapes, such as、、. These powders can affect the lubricant’s performance in several ways:

* Particle size and distribution: larger particles can provide better lubrication but can also increase wear and tear on the surface being lubricated.

* Material compatibility: Some graphite powders may not be compatible with certain materials, leading to issues with wear and tear or contamination.

* Cost: Larger graphite powder particles can be more expensive than smaller ones, especially if they require additional processing or purification steps.

Overall, choosing the right graphite powder is important to achieve optimal lubricant performance, minimize wear and tear, and reduce maintenance costs. It is recommended to consult industry standards, literature, and testing methods when selecting and using graphite lubricants.

(Graphite Lubricant Graphite Micropowder Graphite Powder)

Applications of Graphite Lubricant Graphite Micropowder Graphite Powder

Automotive Industry: Used in engine parts, bearings, and chassis components to reduce friction and enhance performance.

Food Processing Equipment: Provides lubrication in machinery where direct contact with food products must be avoided.

Aerospace: Ideal for high-temperature and vacuum applications, such as in aircraft engines and space mechanisms.

Molding and Casting: Applied to molds and dies to ease release and extend their lifespan.

Medical Devices: Used in equipment where sterility and clean operation are crucial.

Metalworking and Machining: Lubricates cutting and grinding tools, reducing heat buildup and prolonging tool life.

Company Profile

Infomak is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality lubricant and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality lubricant materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Graphite Lubricant Graphite Micropowder Graphite Powder

Q: How is Graphite Lubricant Graphite Micropowder Graphite Powder applied?

A: It can be applied through various methods, including spraying, brushing, tumbling, or as a part of a coating process, depending on the specific powder and application needs.

Q: Is Graphite Lubricant Graphite Micropowder Graphite Powder environmentally friendly?

A: Many dry lubricants are composed of inert materials and are considered environmentally benign compared to oil-based lubricants, but this can vary based on the specific formulation.

Q: Can Graphite Lubricant Graphite Micropowder Graphite Powder be used in place of oil or grease in all applications?

A: While they are effective in many scenarios, there are still applications where liquid lubricants may be more suitable due to factors like load-bearing capacity or speed of moving parts.

Q: How long does Graphite Lubricant Graphite Micropowder Graphite Powder coating last?

A: Lifespan varies depending on the application, environmental conditions, and the specific lubricant used, but they generally offer longer service intervals than wet lubricants.

Q: Is Graphite Lubricant Graphite Micropowder Graphite Powder resistants to water and chemicals?

A: Many dry lubricants are hydrophobic and resistant to chemicals, making them suitable for use in harsh environments. However, performance can vary depending on the chemical composition of both the lubricant and the substance it contacts.

(Graphite Lubricant Graphite Micropowder Graphite Powder)

(Graphite Lubricant Graphite Micropowder Graphite Powder)

Graphite lubricants can have different types and grades, such as polytetrafluoroethylene (PTFE) lubricants, silicone oils, silicone greases, silicone grease, and more. Each type of graphite lubricant has its own properties, including:

(Graphite Lubricant Graphite Micropowder Graphite Powder)

REQUEST A QUOTE

RELATED PRODUCTS

WS2 Tungsten Disulfide Best Engine Oil Additive Lubricant Additive

MOLYKOTE D-321 R Anti-Friction Coating s Air-curing dry-film lubricant 400 ml

TM-3 Graphite Lubricant Can be used for electrical conductivity, lubrication, mold release

Molykote Pd-920 Electronic Digital Quick-Drying Lubricant Pd920 Fluorinated Semi-Dry Film Lubricant

poudre de graphite microfine polve microfino de grafito for lubrication