TR-202 Zinc Butyl Octyl Primary Alkyl Dithiophosphate

TR-EPC02 Ethylene-Propylene Copolymer

Lithium 12-Hydroxystearate Lithium Grease Lithium Based Grease

Graphene Best Oil Additive Engine Oil additive

Graphite Powder Graphite Lubricant Dry Graphite Lubricant

MoS2 Friction Modifier Molybdenum Disulfide

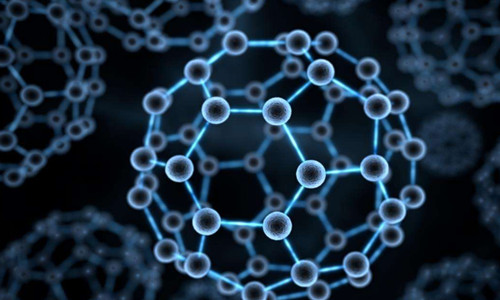

1 Nano-diamond structure characteristics and technical parameters

nano-diamond has a unique spherical shape and luxurious surface functional groups. It is a supramolecular structure formed by a single crystal diamond "core" and a "shell" composed of many functional groups surrounding its outer surface. The surface functional groups are combined with the diamond "nucleus" through chemical bonds and determine the surface chemical properties of the diamond. Its composition is similar to that of the nano-diamond

The synthesis and purification methods are closely related. These oxygen-containing reactive groups provide the possibility for chemical reactions to occur on the surface of diamond particles and help them to disperse in the lubricant stably.

2.Related Studies of nano-diamond oil additive

(1) Advantages of nano-diamond as an oil additive

The application of nanoparticles as anti-friction and anti-wear anti-wear additives is a trend, and the application prospect of nano-diamond is also promising. It has stable chemical properties and does not cause chemical pollution to corrode metal materials such as bearings. With its small particle size and high hardness, it has attracted the attention of many researchers.

(2) Study on surface modification of nano-diamond

The diamond is surface modified with a dispersant containing a long organic chain. This dispersant can use its polar group.

The group interacts with the free hydroxyl groups on the diamond surface so that its end is adsorbed on the diamond surface, and the non-polar alkane chain extends to the outside, which acts as a steric hindrance. The dispersion effect of modified nano-diamond in lubricating oil is also significantly improved, and it can be stably dispersed for three weeks without visible precipitation.

(3) Application of nano-diamond lubricant

Adding nano diamond-graphite-containing composite additives to the internal combustion engine found that the anti-friction and anti-wear anti-wear properties of engine oils have been significantly improved while reducing the content of sulfur, chlorine, phosphorus, fluorine and other elements. The friction coefficient is also reduced by 20% to 30%, the smoothness of the friction pair is improved, and the noise is reduced. The experimental research shows that nano-diamond accelerates the running-in process of the internal combustion engine, and improves the running-in quality and oil film bearing capacity. In a specific range, the anti-wear anti-wear and anti-friction effect is more significant when the load increases. The ultimate load test also showed that the value of the occlusion load was close to twice that of diamond-free oil.

(4) Study on the action mechanism of nano-diamond as a friction modifier additive

Nano-diamond has become a promising application field as a friction modifier additive. Adding nano-diamond to the oil can significantly reduce (up to 8-12%) fuel consumption and increase the life of the internal combustion engine in some cases. There are two explanations for nano-diamond as lubricant oil additive, one is the ball bearing effect, and the other is the thin film effect. The ball bearing effect is believed that the spherical nano-diamonds can act as micro-bearings on the surface of the friction pair, making sliding friction into rolling friction and reducing wear. The thin-film lubrication effect believes that carbon and other elements in nano-diamonds will penetrate the surface of the friction pair substrate, not only filling the micro scratches on the surface of the friction pair, reducing the friction, but also forming a continuous oil film on the surface of the friction pair, The direct contact between the friction surfaces becomes indirect contact. Under high load conditions, the wear is reduced, the extreme pressure of the base oil is increased, and the thin film lubrication effect widely exists in ultra-precision manufacturing and processing systems.

Although nano-graphite can also play a supporting role in lubricating oil, because the lubricating oil added with nano-graphite is opaque, and the market is not right, manufacturers are currently looking for other methods to replace nano-graphite. The best oil additive is a nano- diamond with a size of 5 nm.

Infomak is dedicated to the technology development of special oil additives, combined the technology of nanomaterials developed dry lubricant and oil additives two series. Our products can significantly improve the performance of lubricating oil, improve energy efficiency, effectively protect the lubrication device and extend the oil change cycle, which can satisfy the lubrication oil constantly upgrading for high-end engine oil additives.

If you are looking for nano diamond, please feel free to contact us.